Portfolio

Every project tells a story of innovation, creativity, and collaboration

At Machina, we are passionate about crafting stories that make a difference. Our projects are the result of a dedicated team of professionals with a wealth of experience across various industries. We believe that every project, no matter the size, has the potential to make a significant impact on society.

Please note that while we have worked on many exciting projects, some of our work is subject to non-disclosure agreements, and we are unable to showcase those projects in our portfolio.

HealthTech

TOCI HEALTH

This is and end to end project leaded by Machina. It started with the indication to create a non-pharmacological alternative to Low Back Pain treatment. The results is a Dual therapy system that uses Near Infrared Light and Heat powered by IA to treat muscular pain.

Incubation

We create the concept MVP, validate market, state of the art, IP landscape, and create the technology project.

Science

We create computational models, and ex-vivo experiments to support TOCI effects on pain treatment.

Engineer Development

We develop the complete set of modules from sensors and applicators, to AI that makes TOCI works.

Design

We use user centered design, validating every step to create TOCI.

Manufacture

We validated CDMOs to manufacture TOCI to launch in the USA market.

Business Development

We create a Delaware spin-off and know TOCI HEALTH Inc. is incorporated and partnering with Medical Device Distributors.

Mobility

HAAK

This is and end to end manufacturing project. Haak was developed to create an inclusive mobility option, solving potential areas for improvement of commercial low-cost devices, and taking leverage of the Local Manufacture capabilities.

Incubation

The staring point was a mobility landscape analysis for big cities, considering different scenarios of infrastructure and road problems. As well as the manufacturing landscape on the region.

Design

We use, user centered design, and put special focus on manufacturing techniques for low cost.

Engineer Development

We produce prototypes and validate the improvements with real users.

Manufacture

We validated CDMOs to manufacture Haak with low-cost, while maintaining our commitment to quality and innovation. With our end-to-end manufacturing approach, we ensure that every detail is carefully considered, from design to delivery.

Manufacture

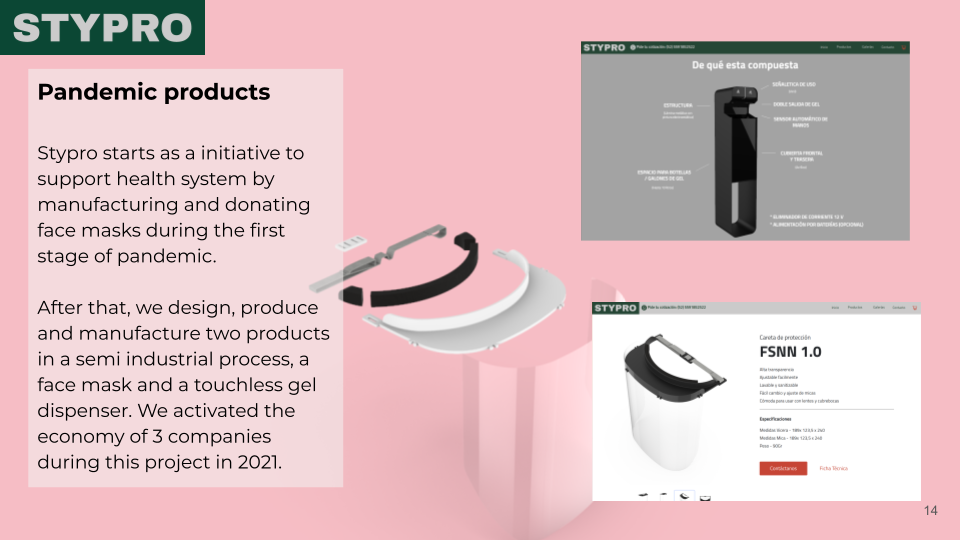

Pandemic Products: Innovative Solutions for Challenging Times

At the height of the pandemic, we worked on several projects to support people in need. In the second stage of the pandemic, we developed two end-to-end projects featured by the brand STYPRO.

Fast Development: Turning Ideas into Products in Just Two Months

To meet urgent demand, we partnered with four experienced companies to manufacture innovative healthtech products in record time. From ideation to finished product, we completed the process in just two months, ensuring that our solutions were available when people needed them most.

Impact: Saving Jobs and Solving Critical Shortages

This projects help 5 companies to maintain employments and solve in a very early stage a shortage for face masks.

Our pandemic products had a tangible impact on people’s lives. By creating innovative solutions like face masks, we helped five companies maintain employment and address critical shortages in personal protective equipment. Our projects were instrumental in enabling healthcare workers and the public to stay safe during a time of unprecedented challenges.

Manufacture: Expert Partnerships for High-Quality Results

We partnered with four expert companies to manufacture our products to the highest standards. By leveraging our collective expertise, we were able to ensure that our pandemic products were safe, effective, and reliable.

Business Development: Bringing Innovative Solutions to Market

We also took care of business development, branding our products, creating e-commerce channels, and partnering with distributors to bring our solutions to market. By taking care of these critical details, we were able to help more people access the healthtech solutions they needed during a time of crisis.

Consumer electronics

Taurus Siphon Coffee Maker

Design

Engineer Development

The result was a stunning siphon coffee maker that embodied the Taurus brand’s unique style and features. We also created a functional prototype that demonstrated the coffee maker’s performance and provided detailed engineering specifications for manufacturing.

Healthtech

Smart Pill Box

Design: A User-Centric Approach to Medical Device Innovation

To meet this challenge, we took a user-centric approach, immersing ourselves in the daily lives of older adults who take multiple medications. Through this research, we gained insights into the unique challenges they face when managing their health, and were able to design a simple, intuitive device that could seamlessly integrate into their daily routines.

The resulting device was not only easy to use, but also lacked an expensive display, making it more affordable to manufacture without sacrificing quality.

Prototype: Taking the First Steps Towards Clinical Validation

Once the design was finalized, we quickly developed basic prototypes to showcase the device’s functionality and gather feedback. Our prototypes allowed the entrepreneurs to continue with the critical clinical validation and manufacturing stages, confident in the knowledge that they had a viable solution that would meet the needs of their target users.

Consumer electronics

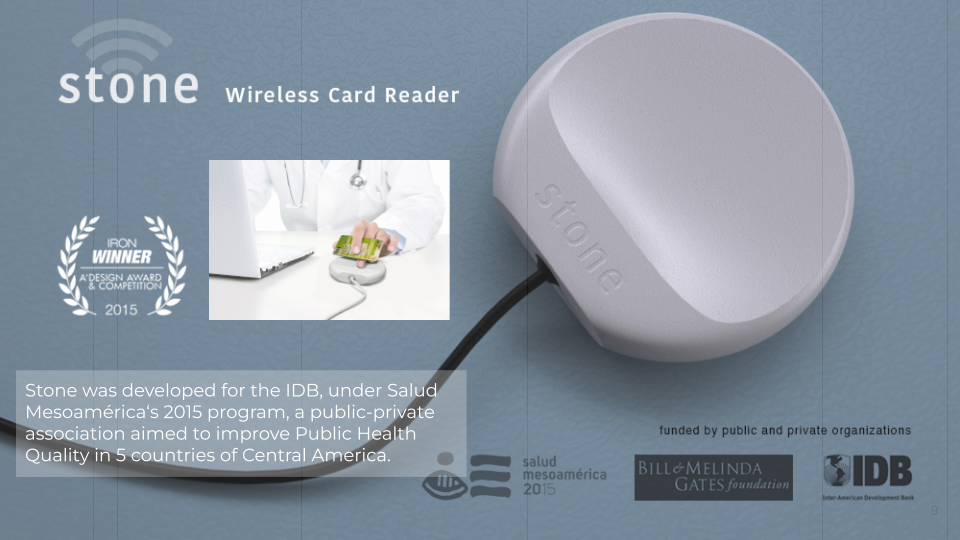

STONE: A Low-Cost, High-Impact NFC Card Reader for Clinical Use

Design: A User-Focused, Intuitive Approach

Engineering: A Lean, Turnkey Solution

Agritech

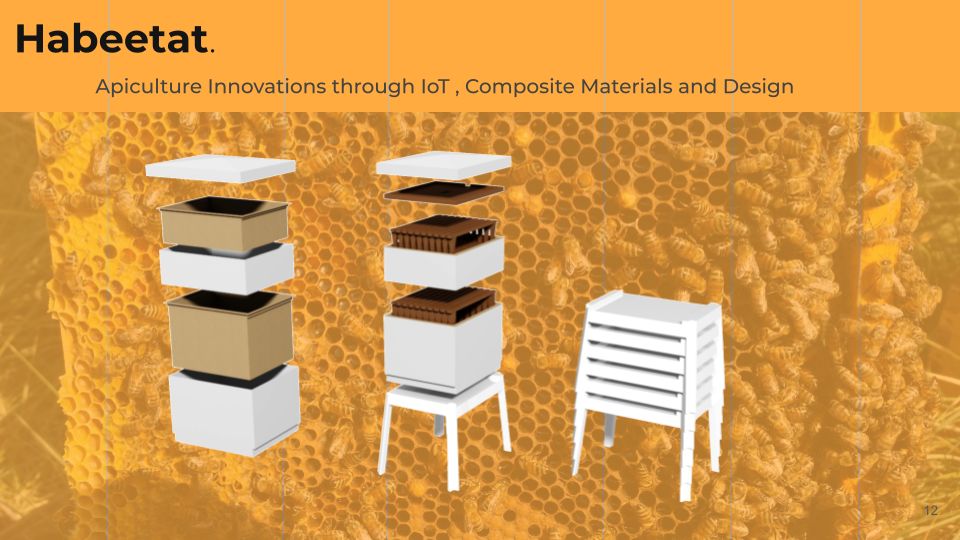

Habeetat: Developing Affordable Solutions for a Global Issue

Beekeepers face a range of challenges, from hive collapse and diseases to monitoring, supplies, and theft. With the global importance of beekeeping in mind, a group of beekeepers approached us for help in developing innovative solutions to address these challenges. This has been one of the most satisfactory projects in which we have collaborated.

Analysis: Understanding the Value Chain and Social/Environmental Impact

We started with an analysis of the beekeeping value chain, as well as the social and environmental impact of the industry. Based on our findings, we proposed a pipeline of projects to drive innovation in beekeeping. We recognized that although many advances are being made globally, they often come with a high cost, making them inaccessible to many beekeepers. Our goal was to develop affordable solutions that addressed beekeepers’ pain points.

Design: Revolutionizing the Hive

We began the innovation process by developing a new type of hive, as the traditional design had not seen any significant innovation in 130 years. Our new hive incorporated manufacturing methods used in the automotive industry, utilizing composites and natural waste materials to create a cost-effective, durable product. We also developed an smart hive as the basis for further innovations to improve bee health and support beekeepers.

Continuing Development: The Intelligent Hive

Our work on this project is ongoing, and we are currently developing an smart hive that will serve as a foundation for new innovations to improve bee health and help beekeepers. By combining our design and engineering expertise with a deep understanding of the beekeeping industry, we are confident that we can continue to create valuable solutions for this vital industry.

Health Tech

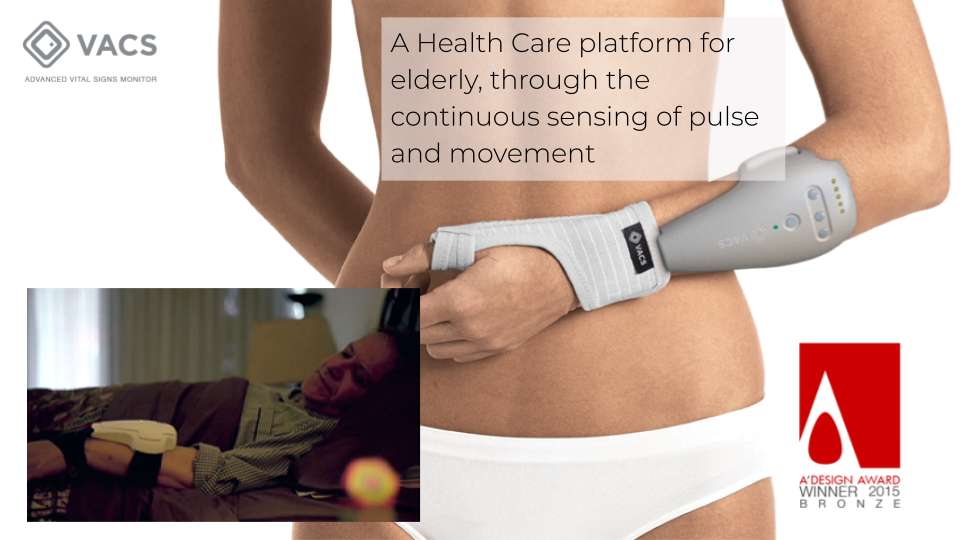

VACS

VACS is a class II medical device that we directed for the Matersys Group, involving over 40 engineers, doctors, and analysts in a three-year development cycle. Our team led the entire product development process, including the creation of a multidisciplinary team, and liaison with Universities and mayor health Institutions.

Medical Need

Our objective was to create a monitoring system that could offer real-time updates on the general health status of users, with a focus on older adults. Our aim was to go beyond just providing a panic button and instead generate preventive programs and detect serious health situations.

Engineer Development

We developed the necessary processes and technologies through a lean development approach, with a focus on monitoring cardiac arrhythmias and user mobility. Our goal was to generate clinically valuable observables for use by healthcare specialists.

Medical Science

We conceptualized the classification of arrhythmias based on cardiac pulse, the inference of health situations through mobility patterns and behavior, and developed clinical tests in collaboration with leading health institutions in Mexico in the fields of cardiology and geriatrics.

Design

We received the “Bronze winner A design award 2015” for the industrial design of the product concept. The device features a sleek and modern design, with an emphasis on usability and ease of use.